The bearing rope of synchronous belt is broken during operation, which is a common failure form. The reason for the failure is that the belt has too much tension on the load rope during the transmission of power, which causes the load rope to break. In addition, when the diameter of the selected active fishing wheel is too small, the bearing rope will bear a large periodic bending fatigue stress during entering and exiting the pulley, and bending fatigue fracture will also occur. We must pay attention to these problems when designing.

There are many materials of timing pulley, which are applicable to different occasions with different requirements. For example, some machines need to have high corrosion resistance, so users can buy synchronous pulleys made of copper or stainless steel. Of course, in order to improve its corrosion resistance, the factory will also carry out various treatments on its surface. Such as natural color oxidation, salt fog blackening, zinc plating, high frequency quenching, etc.

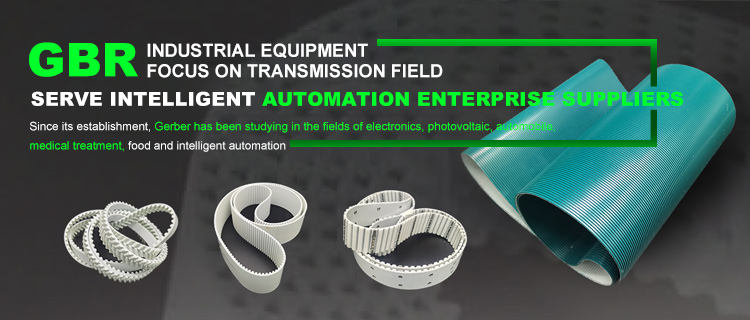

Synchronous belt is a new plastic transmission belt developed by combining the advantages of synchronous belt pulley drive, chain drive and gear drive. It is driven by the meshing of a working surface of the toothed belt and the tooth groove of the toothed belt pulley. Its layer is composed of fiber material or metal material with high tensile strength and small elongation, so that the pitch length of the synchronous belt is basically unchanged during the transmission process, and there is sliding between the belt and the belt pulley during the transmission process, so as to ensure that there is no sliding between the main and the driving wheels. Therefore, it is necessary to understand the failure form when designing the synchronous belt.

When designing the timing pulley, not only the requirements of the use environment should be considered, but also more aspects should be involved. When designing the gear of the synchronous pulley, the manufacturer needs to consider the transmission power, input speed, transmission ratio, etc. of the gear transmission. These are considered to determine the center distance and modulus of the synchronous pulley. Of course, if you know its center distance and modulus, you can directly make the next step. Next, the production personnel will calculate the basic parameters of the gear. When calculating these aspects, the production personnel need to use geometric calculation method. After the basic parameters of the gear of the synchronous pulley are calculated, the contact strength of the tooth surface and the bending strength of the tooth root can be accurately checked* Later, when the production personnel checked the synchronous pulley, they found that its strength was insufficient, and they needed to calculate again.

For customers who have just come into contact with synchronous pulley drive, they may not have a deep understanding of it. Our company has a special catalogue of synchronous pulley products for free download and reference. The typical types and sizes of commonly used synchronous gears are all described in it. The tooth types covered include English teeth, trapezoidal teeth, circular teeth, tooth plates and tooth rods, which can meet most of the requirements

According to customer use requirements. If the customer chooses the style and size of the timing wheel on the data, it is only necessary to provide the following information (we will draw a drawing according to the information provided by the customer for the customer to verify):

① Synchronous wheel style code: such as AF type, AS type, BF type, BS type, etc

② Material (commonly used are 45 # steel and aluminum parts)

③ Tooth shape? (consistent with the tooth shape of the belt used together)

④ Number of teeth?

⑤ Belt width used together

⑥ Center hole diameter?

⑦ Whether the center hole is provided with keyway

⑧ Whether the retaining ring (also called flange) is used on both sides of the synchronous wheel to prevent the belt from falling off

⑨ Surface treatment (blackening is generally required for steel parts, but not for aluminum parts)

⑩ Quantity (if the quantity is large, the corresponding price will be cheaper)

If in doubt, the following are examples of each item:

① Synchronizing wheel style code

According to the actual needs of the equipment, BS type is non-retaining ring type, BF type is non-retaining ring type, and AS type is non-retaining ring type

Two reduction grooves are set to reduce the weight (generally used when the diameter of the synchronous wheel is large